About

HHEA: Hybrid Hydraulic Electric Architecture¶

Hello,

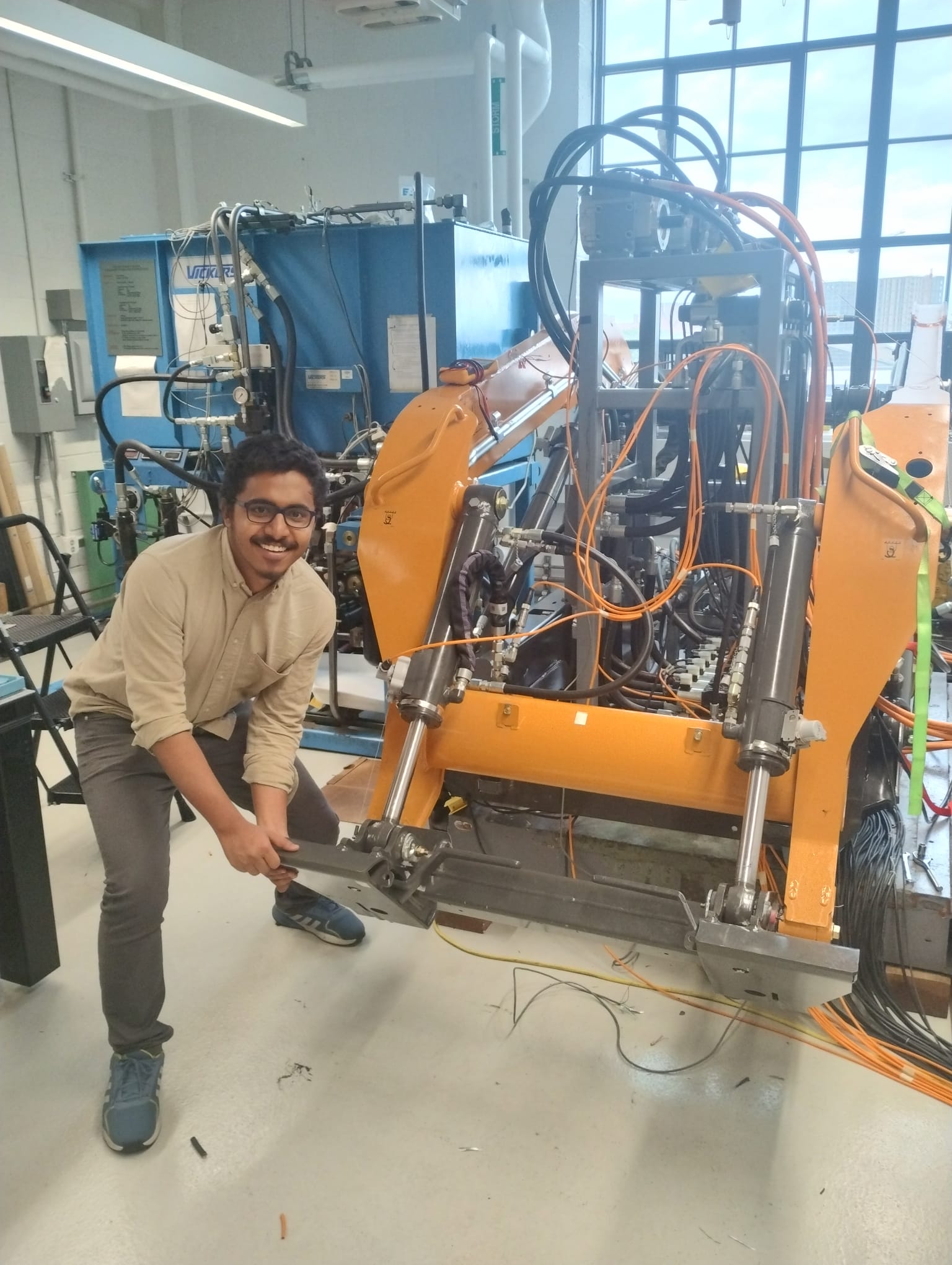

I am Sujeendra Ramesh, and this innovative software framework was developed as part of my master's thesis at the University of Minnesota, Twin Cities, in the field of robotics in 2025.

This project is a part of Dr. Li's Lab, and the project name is HHEA (Hybrid Hydraulic Electric Architecture). I would like to extend my gratitude to my entire team, including:

- Dr. Li

- Jim

- Ravi

- Jackson

- Jacob

- Mahmud

- Zihao

-

Dr. Severson

-

This work is supported by the U.S. Department of Energy Office of Energy Efficiency and Renewable Energy’s (EERE) Vehicle Technologies Office (VTO) under grant number DE-EE0009875. Their support has been instrumental in enabling the research and development presented in this thesis.

Background on HHEA¶

The Hybrid Hydraulic-Electric Architecture (HHEA) is an advanced powertrain designed for off-road electrified vehicles. The prototype developed for this thesis is an electrified Compact Track Loader, which combines the power density of hydraulics with the efficiency and controllability of electric actuation.

Central to HHEA is a set of discrete hydraulic pressure rails, each maintained at different pressure levels. Actuators and motors are connected to valve manifolds that dynamically pair these rails using solenoid valves controlled by the Vehicle Control Unit (VCU). This results in 16 possible pressure pairings, enabling fine control over actuator force and motor torque.

A Digital Displacement Pump (DDP), driven by a Danfoss Editron motor and inverter, supplies and stabilizes the pressure rails based on system demand. Rather than throttling, this centralized flow control enhances energy efficiency.

The system also integrates four smaller motor-generator (M/G) units — Parker GVM210 motors with Sevcon inverters — mounted on hydraulic pump/motor assemblies. These motors serve:

- Left and right propulsion (coupled with hydraulic drive motors)

- Lift and tilt functions (paired with hydraulic actuators)

The M/Gs, sized for ~15% of peak power, handle fine torque modulation, pressure boosting, and energy recovery, effectively "bridging the gap" between discrete hydraulic steps and ensuring smooth, responsive control.

This hybrid approach achieves high efficiency, dynamic performance, and robust control for complex vehicle subsystems.

If you have any questions, please feel free to contact me at rames154@umn.edu.